Creating an International Hub and Talent Pipeline in Glass Science and Technology

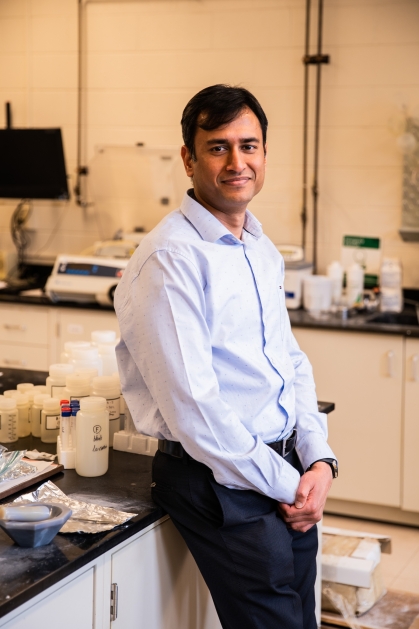

Ashutosh Goel, a professor in the School of Engineering (SoE) Department of Materials Science and Engineering (MSE) and the director of Rutgers’ Corning Glass Science and Engineering Laboratory is quick to point out how glass surrounds us.

“Smartphones and computers need scratch-proof glass screens,” says Goel, who joined SoE in 2014 as a faculty member and to rejuvenate a glass research program at Rutgers, thanks to a grant from Corning Incorporated.

“Every windmill blade has tons of glass in it; glass spun into fiber insulates our homes; and it is playing an increasingly critical role in nuclear waste management.”

Even as he delights in the versatility of glass, he bemoans the US industry’s severe shortage of glass scientists. It’s a challenge he has addressed by building a state-of-the-art lab and a growing network of national and international industry and academic collaborators. In the process, he has established Rutgers as a world-class glass and ceramics research hub that’s working towards solving the issues relevant for our sustainable future, for example, nuclear waste management, and as one of the tangible outputs of his research, creating a well-trained and skilled workforce for the global glass and ceramic industry.

Meeting Nuclear Waste Challenges

“Very few universities today are as big as Rutgers in terms of nuclear waste management,” he states. In the past decade, Goel’s research team has contributed to the daunting clean-up of Hanford site, Washington’s 56 million gallons of underground legacy radioactive waste.

“We helped the US Department of Energy (DOE) in that mission, leading to the point where the DOE has actually begun to pour the first test glass in the Hanford Waste Treatment and Immobilization plant,” Goel recalls.

His legacy waste successes have led him to work proactively on managing waste likely to be generated from advanced nuclear reactors slated for deployment beginning in 2030.

To this end, in the last decade, Goel has amassed a $14.5 million research portfolio, which includes projects funded by the US DOE’s Office of River Protection (ORP); its Advanced Energy Projects Agency DOE ARPA); and its Office of Nuclear Energy to address legacy and non-legacy waste risks.

Creating a Talent Pipeline

US DOE glass scientist Dr. Albert A. Kruger comments, “In the decade-long collaboration between Dr. Goel’s group at Rutgers and the DOE’s Office of River Protection, we have been most fortunate to participate in the education of a generation of scientists who will go on to solve critical environmental challenges in nuclear waste clean-up.”

Creating a skilled and talented workforce is central to Goel’s mission. “If we don’t get future engineers ready for the field of glass technology, the US will lose its global leadership in science and technology, which won’t be good for us,” Goel insists.

“Our program attracts outstanding graduate students interested in glass research and nuclear waste management thanks to the advancements Professor Goel has brought to the SoE and our department,” says Lisa Klein, MSE distinguished professor and department chair. “By securing high-level research grants and important industry and academic partnerships, we are now a leader in these fields.”

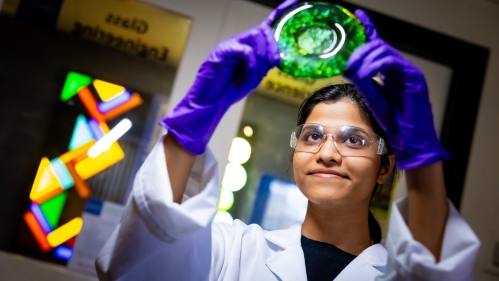

Current doctoral student Nedgine Joseph’s interest in immobilizing nuclear waste via vitrification brought her from Florida to Rutgers specifically to work under Goel. “What captivates me most about glass science is glass’ remarkable versatility,” explains Joseph, who has received three coveted awards: the Corning Glass Age Scholarship; the GEM Fellowship; and a Rutgers Dean’s Fellowship to Broaden Participation.

It is more than likely that she will join the ranks of Goel’s Ph.D. students who, he reports, “are all 100% successfully employed, even having offers in hand before graduating. Their success further supports us as a leader in the field.”

The Tools for Student Success

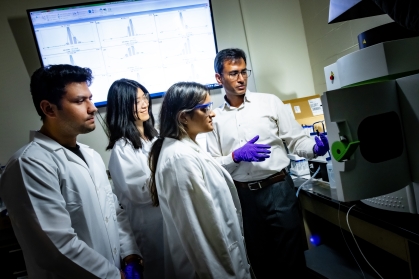

Since joining Rutgers, Goel has transformed an outmoded lab into a truly world-class facility with industry-grade equipment -- from glass furnaces that reach 1700° centigrade to state-of-the-art equipment for probing the chemical composition, structure, and properties of glasses. One such example is inductively coupled plasma–optical emission spectroscopy (ICP-OES), which is used to measure the chemical composition of glasses.

Roy Groething

“ICP-OES is an expensive piece of equipment, usually available in shared university facilities, but our lab has it for our students. Apart from research, we have included this technique in the undergraduate curriculum of materials characterization laboratory course so that our students have an edge over others when they enter industry or graduate school,” Goel says. This level of training and hands-on experience is invaluable for feeding the industry talent pipeline.

A former Ph.D. student from Goel’s group, Nick Stone-Weiss, currently employed as a glass scientist at Corning Incorporated, says working in glass and ceramics while earning his Ph.D. in MSE in 2020 has shaped his career. “Through the Rutgers program, I made several connections as a part of research collaborations with Corning, Washington State University, and others,” he explains.

“Without these connections and my training, I would not have been able to get where I am today and excel in the field of glass science and technology.”

Initially an MS student in MSE, Yingcheng Zhang transferred to the PhD program, graduating in 2023. Today, he is a glass scientist at Nippon Electric Glass/NEG – North America.

Looking back, he recalls, “My fantastic journey as a Ph.D. student has given me not only the essentials for becoming a good scientist but also the soft skills – logical thinking, academic writing, and communication skills – to benefit my professional career.”

Hrishikesh Kamat, a research and development scientist at James R. Glidewell Dental Ceramics Inc., earned his Ph.D. in 2021. His interest in glass science was met in Goel’s lab, for what he says was the most rewarding experience of his academic career.

“Thanks to the MSE department’s strong ties with industry and national labs, I was able to pursue a summer internship at Corning,” he says. Kamat’s practical experience ensured a seamless transition to his current career.

Goel is delighted to establish a lab where students benefit from access to cutting-edge equipment and hands-on experience – as well as opportunities in industry and with leading academic researchers from the US and worldwide. “It has been a long journey,” Goel says. “And I’ve enjoyed every step along the way.”